Understanding the Benefits of Hurricane Impact Windows

Understanding the Benefits of Hurricane Impact Windows

Outline:

– Why hurricanes break windows and why that matters

– How impact-resistant windows are engineered

– Comparing impact windows with shutters, panels, and plywood

– Installation quality, permits, and maintenance essentials

– Costs, savings, and long-term value beyond storm season

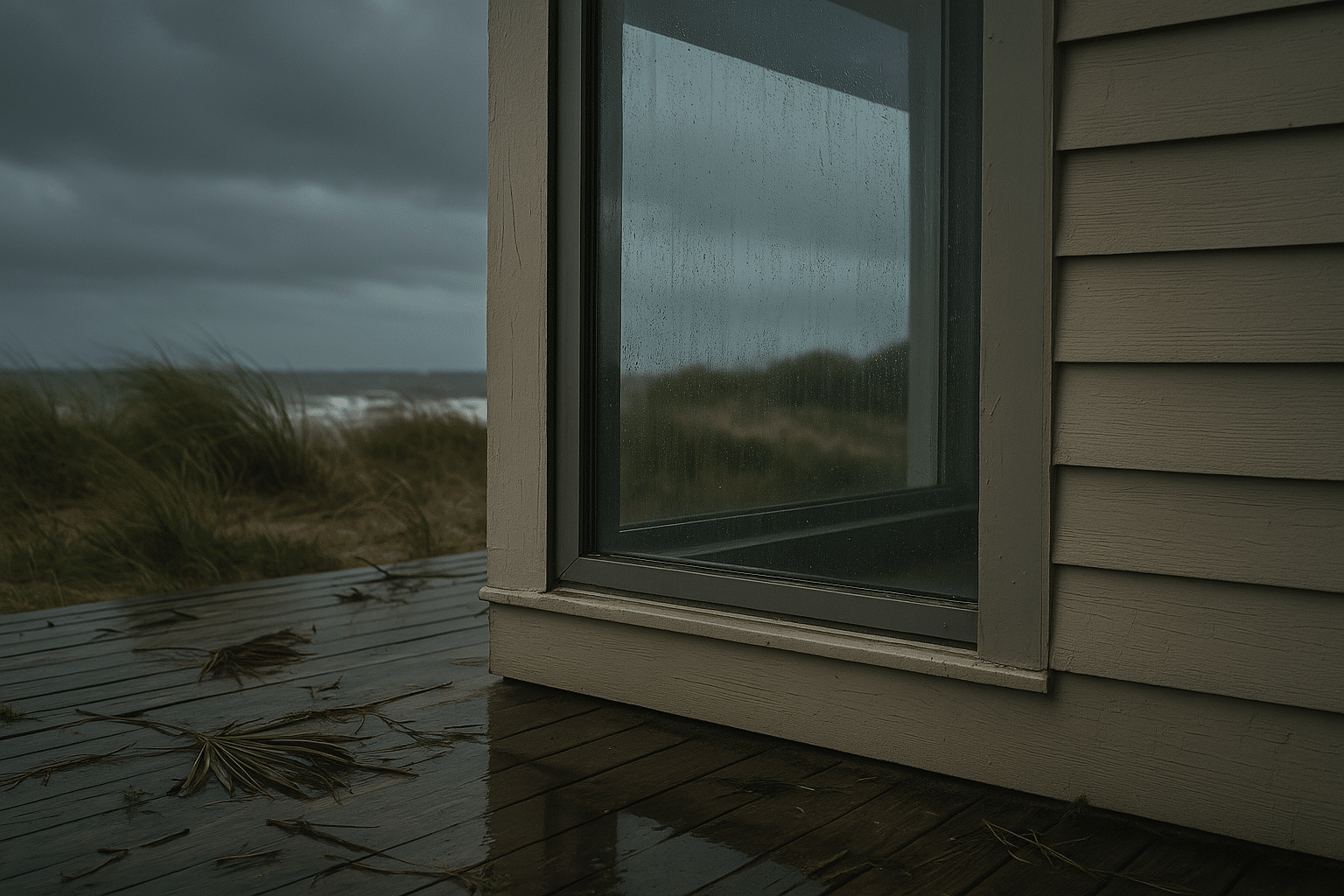

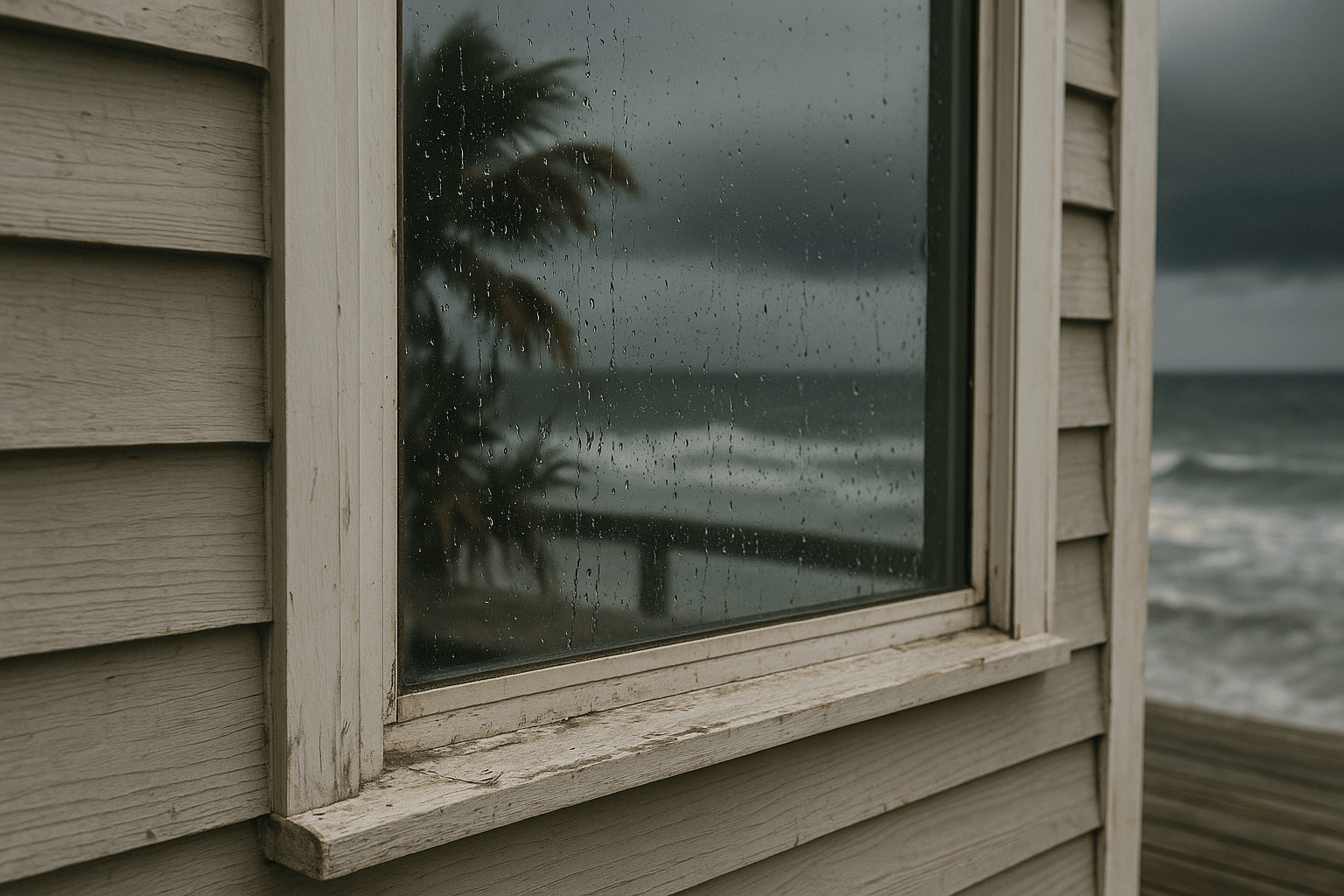

When the forecast turns tense and the sky wears a bruise-colored hue, the integrity of a home often comes down to the clarity and toughness of its glass. Windows are more than openings; they are pressure valves, light-givers, and, in storms, the frontline of the building envelope. Understanding impact-resistant glazing isn’t just about surviving landfall; it’s about everyday comfort, energy performance, and peace of mind. This guide walks through how hurricanes threaten windows, what modern impact designs do differently, how they compare with other protective options, and what to consider before, during, and after installation.

Hurricanes, Pressure, and the Window Weak Point

In calm weather, windows simply frame the day; in a hurricane, they become a structural test. Wind is only part of the story. The real challenge is the combination of windborne debris, fluctuating pressure, and water intrusion that can unravel a building’s defenses. As wind accelerates around a structure, it creates positive pressure on the windward side and negative pressure (suction) on the leeward side and roof. If a standard window fails, the sudden breach allows wind to pressurize the interior, forcing the roof and wall connections to work far harder than they were meant to. That’s why protecting glazed openings matters—keeping the envelope intact helps the whole house resist uplift and lateral loads.

Consider how debris turns into “missiles.” Roof gravel, branches, and fragments of fencing become high-speed projectiles that can shatter ordinary glass. Impact testing in laboratories often simulates this with heavy wooden missiles striking at freeway speeds, followed by hours of cyclic pressure to mimic gusts. The goal is not to avoid cracks entirely, but to prevent perforation and keep the opening closed to air and water. Typical wind loads for severe coastal events can exceed 40 to 60 pounds per square foot on components, a force that tests both the glass and the frame anchorage. Meanwhile, rain driven by those winds searches for the tiniest path through seals and joints.

The most common failure modes during extreme storms include:

– Brittle fracture of monolithic glass from debris impact, leading to shards and an open hole.

– Frame disengagement due to inadequate fasteners or deteriorated anchoring into the wall.

– Sealant failure at perimeters, allowing water penetration and pressure equalization in the wrong places.

– Mullion or sash deformation under repeated suction and pressure cycles, causing latches to pop.

Real-world examples highlight the chain reaction. A single broken pane can allow wind to inflate a room like a balloon, popping ceiling drywall and forcing attic access panels open. Add negative pressure over the roof and uplift forces rise sharply. By contrast, when windows hold—even if cracked—the envelope remains a barrier, interior pressure stays managed, and the structure can ride out gust cycles with fewer cumulative stresses. In short, windows are not merely at risk; they are also the guardians of everything downstream in a storm’s physics.

How Impact-Resistant Windows Are Built to Stay Put

Impact-resistant windows are a system, not just thicker glass. Their centerpiece is laminated glazing: two or more panes bonded to a clear, resilient interlayer. If the glass cracks on impact, the interlayer stretches rather than rupturing, holding fragments in place and keeping the interior sealed from direct airflow. Common interlayers include polyvinyl butyral and newer ionoplast formulations, with thicknesses tuned to resist both “missile” strikes and the grueling push-pull of cyclic storm pressures. The result resembles a transparent safety net—quietly invisible most days, but ready when debris flies.

The frame matters as much as the glass. Materials vary—reinforced vinyl, aluminum with thermal breaks, fiberglass, and wood-clad constructions each bring different strengths in stiffness, corrosion resistance, and energy performance. Reinforcement can include internal ribs or steel inserts that limit deflection. Multi-chamber profiles in vinyl and fiberglass improve rigidity and thermal performance, while well-designed aluminum profiles rely on thickness, geometry, and thermal breaks to balance strength with condensation control. Hardware complements the frame: robust hinges, continuous or multi-point locks, and stout keepers ensure the sash remains seated during suction cycles.

Look for performance ratings that combine impact resistance and design pressure (DP) values. A typical high-wind product will be tested with large-missile impacts followed by cycles of positive and negative pressure to verify that it doesn’t rupture or unlatch. Water resistance ratings matter, too, because keeping rain out during wind events is part of the same mission. While specific standards and regional approvals vary, the essentials are consistent:

– Laminated glass resists penetration and retains fragments after cracking.

– Frames and fasteners distribute loads into the structure without excessive deformation.

– Perimeter sealing and drainage paths manage water that inevitably arrives in heavy wind-driven rain.

– Locks and hinges are sized for repeated pressure cycles without loosening.

Thermal and acoustic performance ride along as quiet bonuses. Laminated configurations often reduce outside noise by several decibels compared to standard double-pane setups, and low-emissivity coatings can bring down heat gain. Even the interlayer helps block a large portion of UV energy that fades fabrics and floors. In short, impact windows combine a safety technology with everyday performance features, turning a storm tool into a year-round upgrade.

Impact Windows vs. Shutters, Panels, and Plywood

Homeowners weighing protection strategies often compare impact windows with deployable solutions like shutters, storm panels, or plain plywood. Each path can meet code in many regions when installed correctly, yet the user experience and performance envelope differ meaningfully. Impact windows are always “on,” eliminating last-minute rushes to mount panels when a storm track shifts overnight. Shutters and panels, on the other hand, can offer robust defense at lower initial cost but demand time, storage, and safe access—especially challenging for upper stories or for residents away from home when warnings arrive.

Cost comparisons vary by region and opening size, but broad ranges are informative. Installed impact windows may run from the high tens to low hundreds per square foot depending on frame material, glass makeup, and complexity (arches, egress, or large sliders tend to increase costs). Quality shutters and removable panels can be significantly less per square foot, while site-cut plywood is cheapest upfront but the most labor-intensive and least durable. Over a decade, recurring maintenance, repainting, storage, and deployment labor can narrow the initial savings of temporary systems.

Performance and practicality distinctions include:

– Readiness: Impact windows provide constant protection. Shutters and panels require installation before each event.

– Light and visibility: Laminated glazing maintains daylight; opaque panels darken interiors, and even some shutter types reduce light and ventilation when closed.

– Human factors: Deployable systems demand safe ladder work, coordination with travel plans, and storage space. Impact windows simplify logistics for multi-unit buildings or absentee owners.

– Daily benefits: Impact glazing adds noise attenuation, UV filtration, and potential energy gains; shutters and plywood add little outside storm periods.

– Risk of error: Missing a single second-floor panel or a poorly fastened fastener can create a weak link; windows reduce the chance of a deployment mistake.

Shutters and panels remain solid choices for specific budgets or historic facades where window replacement is complex. In some cases, a hybrid strategy makes sense—impact windows on hard-to-reach openings and deployables on easily accessed ones. But for many households, especially where storm threats are seasonal but unpredictable, the convenience and continuous protection of impact glazing are compelling. It’s the equivalent of buckling a seat belt long before the road turns rough, with the added perk of everyday comfort gains.

Installation Quality, Codes, and Maintenance Essentials

An impact window earns its keep only if it is anchored, flashed, and sealed to behave like part of the wall. Proper installation begins with accurate measurement and a plan for the specific wall type—masonry, wood frame with sheathing, or concrete block. Fasteners should match the substrate and be long enough to embed adequately into structural members. Sill pans or formed flashing help direct incidental water outward, while back dams and compatible sealants reduce the chance of leaks under wind-driven rain. Drainage paths (weep holes) in many frame systems are intentional; they should remain clear so that water that does enter can exit rather than pressurize the interior of the frame.

Permits and inspections are not box-checking exercises; they ensure the assembly meets local wind, impact, and water-resistance requirements. Labels or documentation normally indicate design pressures and the impact rating for each unit. Installers should avoid over-shimming that twists frames, and they should verify square, level, and plumb before setting fasteners. Expanding foam, if used, needs to be a low-expansion formulation compatible with the frame material to prevent bowing. Exterior sealant joints should be sized and tooled to allow for thermal movement, with proper backer rod to maintain the correct shape and thickness for longevity.

Maintenance is less glamorous than new glass but just as important over the life of the window. Simple routines go a long way:

– Rinse coastal salt and grime from frames and glass periodically to prevent corrosion or staining.

– Clear weep paths and check that capillary covers are unobstructed.

– Inspect gaskets, glazing beads, and sealant lines for drying, cracking, or gaps, and renew as needed.

– Lubricate locks and hinges lightly with manufacturer-compatible products to maintain smooth engagement.

– Check interior humidity and ventilation to reduce condensation risk during seasonal shifts.

After a storm, treat inspection like a short checklist: look for cracked laminates (which can still be intact but damaged), confirm latching, and examine perimeter joints for signs of water tracking. Document anything unusual for insurance records. Even when everything appears sound, scheduled checkups help catch slow-developing issues such as UV-exposed sealants or settling that changes alignment. Good installation and modest upkeep stack the odds in your favor, ensuring the window performs like a structural element rather than decorative trim when the wind starts to roar.

Beyond Storms: Energy, Noise, Security, and Long‑Term Value

Impact windows often earn their reputation in a single night of high winds, but their value plays out 365 days a year. The laminated glass and multi-seal frames typically provide better air tightness than older units, which can translate into more stable indoor temperatures and fewer drafts. With low-emissivity coatings and optimized spacers, upgraded units can cut cooling loads meaningfully in sunny climates, with many households seeing double-digit percentage reductions in peak-day air-conditioning energy. In winter climates, reduced infiltration and improved U-values support comfort around seating areas near glass—no more avoiding the window seat when the temperature drops.

Noise reduction is another quiet victory. Laminated constructions can push Sound Transmission Class values into the low-to-mid 30s for common residential assemblies and higher for heavier builds. The subjective result is less thump from passing trucks, softer sirens, and a calmer interior during afternoon gusts. UV filtering also protects furnishings; interlayers and coatings can block the vast majority of UV, reducing fading of floors, fabrics, and artwork. Security benefits add one more layer: laminated panels are harder to breach quickly, which can discourage opportunistic break-ins by demanding more time and noise.

Financially, the calculus mixes upfront cost with savings and incentives. Homeowners in high-wind regions may qualify for insurance credits when verified impact protection is installed on all openings. Utility savings vary with climate and window area, but efficiency gains plus potential incentives can offset a portion of the investment. Resale value often reflects curb appeal, quieter interiors, and documented wind mitigation—features buyers recognize immediately. To set realistic expectations:

– Energy savings tend to accumulate season by season rather than erasing utility bills overnight.

– Insurance discounts depend on complete opening protection, documentation, and local risk models.

– Payback improves when replacing failing or single-pane units, or where noise and UV are real pain points.

Perhaps the most meaningful return is intangible: confidence. Knowing that the home is ready without a scramble changes the emotional script when advisories pop up. Instead of hunting for panels, you check latches, bring in patio furniture, and move on to the truly important tasks. The storm may still growl outside, but indoors the soundtrack becomes a muted drumbeat—proof that planning, materials science, and good installation have done their quiet work.

Conclusion: Choosing Impact Windows with Clarity

For homeowners in storm-prone regions—or for anyone seeking calmer, more efficient interiors—impact-resistant windows offer a practical, well-rounded upgrade. They preserve the building envelope when wind and debris test the structure, simplify storm preparation, and deliver everyday gains in comfort, acoustics, and UV protection. Compare alternatives honestly, set expectations around costs and maintenance, and insist on careful installation and documentation. With those steps in place, your windows can become quiet guardians in fair weather and fierce squalls alike.