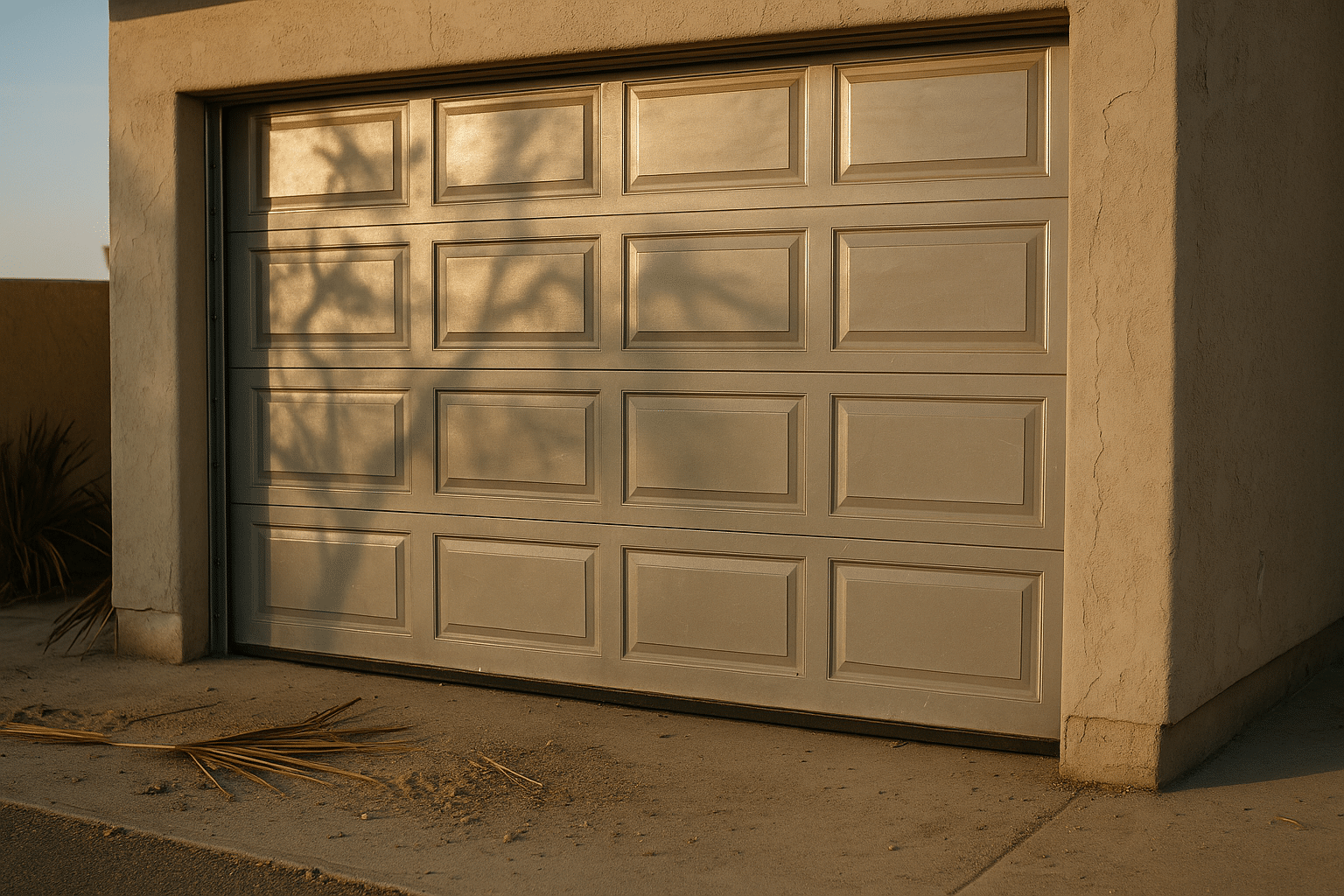

Understanding the Benefits of Impact Garage Doors

Outline and What You’ll Learn

Impact garage doors have moved from niche to necessity in many neighborhoods. This article maps the real-world benefits you can expect by focusing on three pillars—security, durability, and insulation—so you can decide if the upgrade fits your home, climate, and budget. Think of it as a guided tour: we start with a quick blueprint of the journey, then dive deep into how materials, engineering, and installation practices translate into protection and comfort you can feel every day.

Here is the road map you’ll be following, with practical takeaways under each stop:

– Security: How reinforced skins, heavy-gauge tracks, and improved locking strategies resist forced entry and storm-driven impacts; what “layers of defense” look like in a garage setting; how smart alerts complement physical strength without replacing it.

– Durability: Why metals, composites, and finishes matter; how coastal exposure, salt spray, and UV affect hardware life; where cycle ratings, corrosion protection, and maintenance move the needle on total ownership cost.

– Insulation: What R-values mean in practice; the role of polyurethane vs. polystyrene cores; why perimeter seals and thermal breaks influence comfort, humidity control, and even noise levels in attached living spaces.

– Codes and testing: How standardized impact and cyclic pressure tests help compare options; why local building requirements and wind maps shape what’s permitted on your street and roofline.

– Installation and upkeep: The case for professional install, proper track alignment, correct spring sizing, and post-storm inspections; simple routines that prevent premature wear.

By the end, you will be able to compare non-impact and impact-rated doors in a straightforward way. You will also have a checklist that ties features to outcomes—less rattling in high winds, cleaner lines against prying attempts, smoother operation after years of cycles, and more stable temperatures in adjacent rooms. If you like your information concrete and actionable, you’re in the right place, because each section connects lab-style specifications to street-level results homeowners actually notice.

Security: Layered Protection Against Intrusion and Storm Breach

Security for a garage door isn’t just about a lock; it’s about reducing every opportunity for entry or failure. Impact-rated doors start with stronger skins—often thicker steel or laminated composites—paired with reinforced end stiles and heavier tracks. The goal is to hold the plane of the door in place even when a crowbar, a flying branch, or a pressure pulse tries to bend it off the guides. In practice, that means fewer weak points around panel seams, hinge fasteners, and track brackets where intruders or wind loads tend to exploit flex.

Consider how a typical attack unfolds: a thief tests the top panel for give, tries to pop the door out of the track, or targets the emergency release if visible through a window. Impact designs counter with tighter top astragals, anti-lift brackets, and tamper-resistant fasteners. When paired with an interior slide bolt or a shielded latch, the whole system resists prying leverage that would defeat a lighter assembly in seconds. During severe weather, the same reinforcements help keep the door intact, reducing the risk of a sudden garage breach that can pressurize the structure and jeopardize roof connections.

Useful, low-cost add-ons support that core strength:

– A manual interior lock for overnight or vacation use, creating a mechanical backup if power fails.

– Enclosed tracks and heavy-duty track brackets that reduce lift points and twist under load.

– Narrow sightlines and laminated glazing (if windows are desired) to deter release-cord fishing while still admitting daylight.

– Quiet, torque-matched openers with rolling codes and door position sensors; these don’t replace physical security, but they remove common digital shortcuts.

Standards help buyers calibrate expectations. Many impact-rated doors are tested against debris impacts followed by cyclic pressure protocols designed to emulate wind events found in coastal storms. Typical residential design pressures range widely by model and opening size, but ±35 to ±60 psf is common, with higher ratings in hurricane zones. The practical translation is simple: a door that stays in its tracks under cyclic loading also resists crowbar flex and kick-in attempts more effectively. Post-storm assessments routinely identify garage door failure as a trigger for larger structural damage, so preventing that failure is a security win and a resilience win rolled into one.

Finally, security works best in layers. Combine the reinforced door with good exterior lighting, a tidy perimeter (no ladders or tools visible), and sensible habits such as keeping the transmitter in the house rather than clipped to the car visor. When every layer removes an easy opportunity, you shift risk away from your address without turning your garage into a fortress.

Durability: Materials, Finishes, and Hardware That Go the Distance

Durability shows up in small daily moments: a door that tracks smoothly on a cold morning, paint that shrugs off summer sun, hardware that doesn’t corrode after a salty wind. Impact garage doors tend to be built with longevity in mind because the same reinforcements that handle debris also tame routine wear. Start with the face material. Galvanized steel offers strong dent resistance and good value; aluminum resists corrosion and cuts weight; fiberglass or composite skins can mimic traditional textures while handling moisture gracefully. The inner construction—double- or triple-layer builds with bonded cores—keeps panels from oil-canning and reduces stress on hinges.

Finishes and coatings matter. Zinc galvanization under a baked-on or powder finish helps steel resist rust, while marine-influenced markets often favor additional coating steps. Hardware deserves equal attention. Torsion springs commonly range from 10,000 to 25,000 cycles; higher-cycle options make sense for households that open and close the door multiple times per day. Nylon rollers reduce noise and do not require constant lubrication, while sealed bearings protect against grit. Track thickness and bracket gauge are not flashy features, yet they decide whether a door stays aligned after years of operation and the occasional bump from a fender.

In coastal or high-UV regions, durability upgrades pay off quickly:

– Stainless or coated fasteners to fight salt corrosion at hinges and brackets.

– Heavier end stiles that diffuse hinge loads across a larger area, limiting panel fatigue.

– Bottom seals with UV-stable compounds that remain flexible across seasons and shed wind-driven rain.

– Drip edges and weep paths that move water away from seams and fastener heads.

Independent testing and local code approvals provide a baseline for performance under stress, but everyday lifespan hinges on maintenance. A short checklist—clean tracks, lubricate hinges and springs with the right product, inspect weatherstripping yearly—can double the time between repairs. If you live near the coast, rinsing salt film monthly is a tiny effort that prevents finish creep and rust blooms. Small habits compound into longevity.

Durability also has a budget dimension. While an impact-rated door may carry a price premium, its reinforced build often reduces panel replacement, realignment calls, and hardware swaps over the years. In some regions, insurers acknowledge reduced loss potential with policy considerations; even when they do not, the avoided hassle of post-storm repairs and fewer service visits represent value that shows up in both costs and peace of mind.

Insulation: Thermal Performance, Noise Control, and Everyday Comfort

Insulation is where comfort and efficiency meet. An impact garage door with an insulated core does more than buffer heat; it steadies indoor conditions, protects stored items, and calms street noise. Two common core materials dominate: polystyrene panels and polyurethane foam. Polystyrene typically delivers moderate R-values in a cost-conscious package, while polyurethane, which bonds to the skins as it foams in place, fills voids more completely and usually posts higher R-values for the same thickness. For example, a two-inch polyurethane core often posts published R-values in the low to high teens, whereas similar polystyrene constructions trend lower. Real-world performance will vary, but the hierarchy is consistent.

Thermal breaks in the panel edges and along stiles, together with robust perimeter seals and a quality bottom astragal, make or break that performance. Any gap around the jambs becomes a chimney for conditioned air. By pairing insulated panels with tight weatherstripping, you limit infiltration that would otherwise undermine the R-value on the label. The payoff shows up in adjacent rooms over the garage—bonus spaces, bedrooms, or home offices—that no longer swing wildly with the seasons. In colder climates, that can reduce run times for heaters serving over-garage spaces; in warmer climates, it moderates the heat sink effect that radiates into the house at night.

Insulation can also dampen sound. While garage doors are not typically marketed with formal acoustic ratings, added mass and a bonded core reduce panel resonance and airborne noise. The change may be modest on paper, yet the subjective difference at the driveway and in nearby rooms is often noticeable: less clatter when the door moves, softer traffic drone, reduced echo in the garage itself.

When comparing insulation packages, look beyond a single number:

– Core type and thickness: polyurethane usually outperforms polystyrene at equal thickness.

– Panel construction: multi-layer, bonded designs resist vibration better and feel more solid.

– Perimeter sealing: high-quality side and top seals plus a pliable bottom gasket are non-negotiable.

– Thermal bridging: breaks at stiles and rails keep heat from short-circuiting through metal paths.

For attached garages, even a few degrees of temperature stability can protect paints, batteries, and finishes stored on shelves. If you use the garage as a workshop or fitness area, insulation moves from “nice-to-have” to an everyday upgrade you feel in minutes. Pair it with a quiet, properly sized opener and balanced springs, and the whole system operates with a calm, confident tone that makes early departures and late returns less disruptive for everyone.

Conclusion and Buyer’s Checklist: Bringing It All Together

The case for impact garage doors is straightforward: stronger skins and tracks protect against forced entry and storm debris; carefully chosen materials and hardware deliver long service life; bonded cores and seals stabilize temperature and reduce noise. The right choice depends on where you live, how you use the garage, and the adjacent rooms you want to keep comfortable. If you picture your garage as a weak link in home security or a hot-cold buffer zone that affects nearby spaces, this is a targeted way to upgrade both resilience and daily living.

Use the checklist below to turn the ideas in this guide into a confident purchase:

– Confirm your local wind and impact requirements; ask for documentation showing compliance with applicable test standards and local approvals.

– Compare panel constructions: look for multi-layer builds, reinforced end stiles, and track hardware that matches the door’s weight and width.

– Prioritize insulation and sealing if the garage is attached or occupied; assess perimeter seals, bottom astragal quality, and thermal breaks.

– Choose corrosion-resistant fasteners and finishes if you live near salt or industrial pollution; plan a simple rinse-and-inspect routine.

– Ask about cycle ratings for springs and rollers; opt for higher-cycle components if your household cycles the door many times per day.

– Pair physical security with sensible habits and basic tech: interior slide locks, rolling-code controls, and door position alerts add layers without complexity.

Installation quality determines how well all those features work in real life. Professional installers will size springs correctly, plumb and level tracks, set opener limits, and confirm balance so the door stays put at mid-travel. After major storms—or once a year—schedule a quick inspection for fastener looseness, seal wear, and track alignment. Small tweaks prevent small problems from becoming big repairs.

For homeowners who want fewer surprises and more control over comfort and safety, an impact-rated, insulated door is among the most well-regarded upgrades on the exterior envelope. It supports your roof in a blow, keeps tools and sports gear in better condition, and subtly quiets the soundtrack outside. Choose carefully, install correctly, maintain lightly, and the door will feel almost invisible—reliable, sturdy, and quietly doing its job day after day.