Understanding the Role of Land Clearing Contractors

Why Land Clearing Contractors Matter: Introduction and Outline

Every successful project starts not with walls or windows, but with a steady transformation of raw ground into a predictable, buildable surface. Land clearing contractors orchestrate that transformation, blending site preparation, excavation, and demolition into a single, carefully sequenced effort. Their work sets the tone for everything that follows: how foundations will sit, how water will flow, how trucks will access the site, and how safely crews can operate. When the early moves are right, schedules shorten, budgets hold, and future headaches never materialize. When they’re wrong, the ground itself argues back—through settlement cracks, ponding rain, and costly rework.

To show how these pieces fit together, here’s the structure of this guide and what you can expect from each section:

– Site Preparation: field surveys, vegetation removal, access, drainage, and erosion control

– Excavation: cut and fill, trenching, grading tolerances, and soil management

– Demolition: structural takedown strategies, material recycling, dust and noise control

– Environmental and Permitting: protections for water and habitats, approvals, and documentation

– Hiring for Success: evaluating experience, safety, scope clarity, and cost controls

Clearing may appear simple—remove what’s in the way and shape what remains—but beneath that simplicity lies a web of constraints. Utilities may cross the property at inconvenient depths, soils may shift from firm sand to slick clay across a few meters, and the weather can swing from dusty drought to axle-deep mud in a week. Competent teams anticipate these variables. They perform soil tests to find compaction targets, flag live utility corridors, and phase work so erosion control and access roads lead, not lag. They also align demolition and excavation sequences so that debris hauling doesn’t choke material deliveries and that temporary slopes remain stable until final grades lock in.

Think of land clearing like setting up a chessboard: the opening determines the entire game. A well-prepared subgrade gives foundations a consistent bearing surface. Smart excavation limits export and import by balancing cuts and fills. Thoughtful demolition preserves salvage value and reduces landfill fees. In the pages ahead, we dig into the practical decisions, data points, and field-tested tactics that help contractors deliver durable, build-ready sites with fewer surprises.

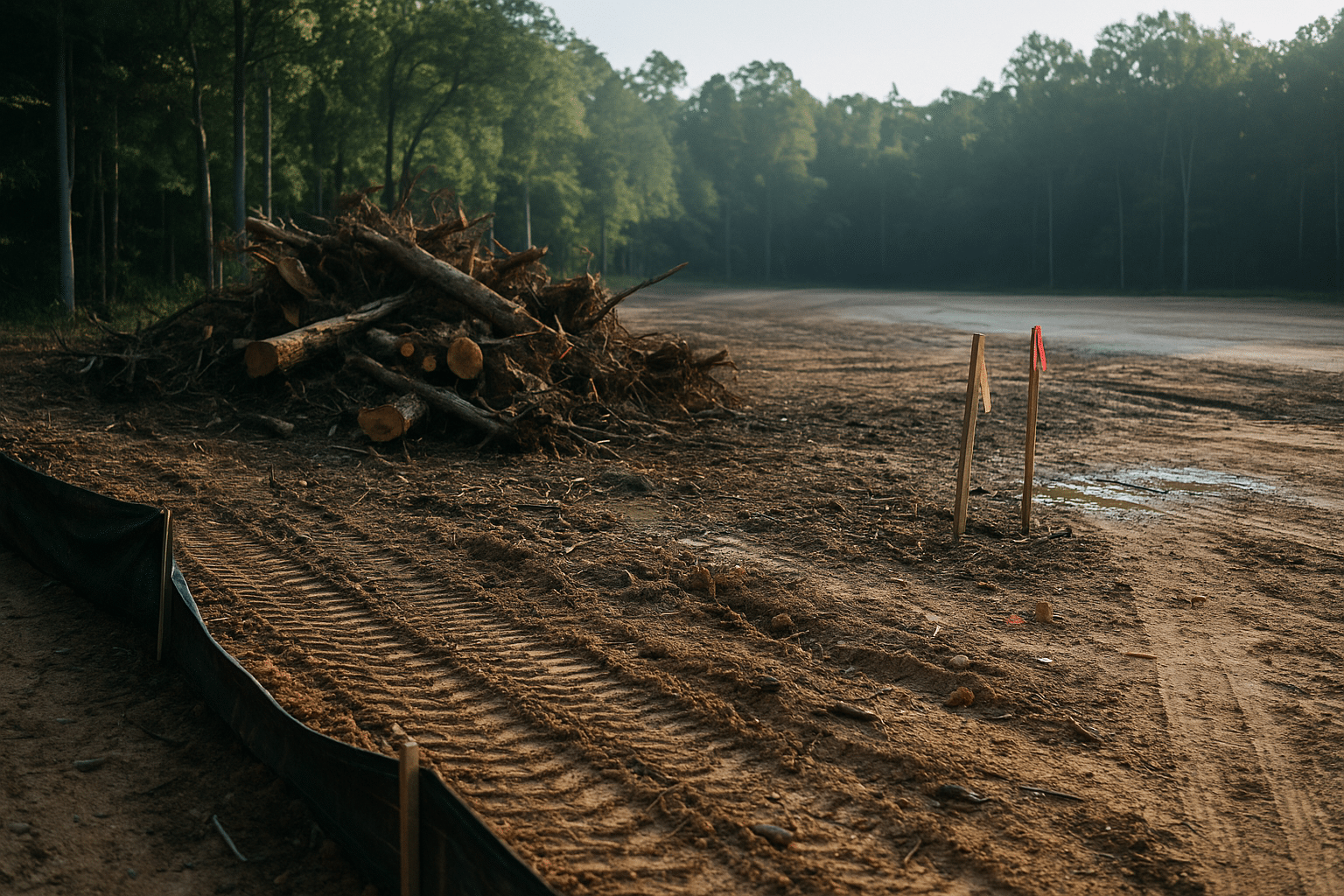

Site Preparation: From Survey Stakes to Stable Subgrades

Site preparation begins with control and access. Crews confirm boundary lines, set benchmarks, and establish a clear baseline for elevation checks. Vegetation removal follows—trees, stumps, brush, and roots are cleared to eliminate organic material that could decay and settle under future loads. Topsoil, rich in organics and moisture, is typically stripped and stockpiled for later landscaping; leaving it beneath slabs or pavements invites long-term movement. Temporary access roads come next to keep trucks out of the mud and minimize ruts that turn into drainage problems.

Water management is where site prep often wins or loses. Proper drainage starts well before permanent systems are in place. Contractors grade temporary swales, install inlet protection, and deploy perimeter controls to keep sediment on-site. Typical interim slopes target enough fall to move water off work surfaces—often 1–2 percent for flat work areas—without causing erosion. Managing fine silts becomes essential after rain; a sticky surface can triple cycle times for hauling and compaction if not addressed promptly.

Compaction and proof-rolling convert disturbed ground into stable subgrade. Field teams adjust moisture toward an optimal range that allows soil particles to interlock under compaction energy. A common target in many specifications is achieving 90–95 percent of a laboratory maximum density, verified by in-place testing. While the lab numbers are technical, the field logic is simple: dry soil won’t knit together; saturated soil pumps under load. The sweet spot is moist, workable, and firm under a loaded truck.

Different soils demand different tactics:

– Sands: drain quickly and compact well at slightly lower moisture; watch for raveling slopes.

– Silts: sensitive to water; too wet and they lose strength fast, requiring drying or stabilization.

– Clays: hold water and expand; control moisture, consider lime or cement treatment where specified.

Underground risk management is integral during prep. Utility locating with flags and paint defines safe zones and dig windows, allowing layout to avoid conflicts. Clearing should account for tree protection around specimens to be preserved; fencing and root-zone buffers prevent accidental damage. Traffic plans keep heavy equipment on designated routes, reducing cross-contamination between clean and disturbed areas. By the end of site prep, the project should have predictable access, controlled runoff, known subgrade performance, and clear markers for where foundations, utilities, and pavements will go.

Excavation: Moving Earth with Precision

Excavation is equal parts measurement and movement. Before the first bucket dips, crews compare existing topography with the design surface to estimate cut and fill volumes. The closer the balance, the fewer trucks needed for import or export, which protects budgets and traffic plans. Earthmoving is then sequenced: rough cut areas first, stockpile suitable fill nearby, and place materials in controlled lifts to achieve density and prevent future settlement. Benchmarks and grade stakes guide production so that operators shape to tolerances, not hunches.

Matching equipment to the task is a practical way to manage cost and schedule. Tracked dozers handle bulk pushing over short distances, while excavators load trucks efficiently where haul routes are ready. Loaders shine in stockpile management and blending materials. Graders finish surfaces to tight tolerances, and compactors lock in density. Productivity varies widely by material and haul distance, but a small to mid-sized excavator might load on the order of dozens of cubic yards per hour under favorable conditions, while longer wet hauls can cut that rate dramatically. Planning for weather—especially freeze-thaw cycles or seasonal rains—can be as valuable as adding another machine.

Subsurface work demands deliberate safety and stability. Trenching for utilities requires protective systems once depths and soil types exceed safe self-supporting limits. Many safety codes call for sloping or shoring based on soil classification; a common rule of thumb in weak, granular soils is to avoid steep walls and provide safe entry points. Short, stepped benching and staged installations reduce collapse risk while keeping progress steady. Marked exclusion zones keep bystanders and nonessential traffic away from swing radii and dump points.

Soil management is a continual decision tree:

– Keep: well-graded material with low organics, suitable for structural fill.

– Improve: adjust moisture, blend with better soil, or stabilize where allowed by design.

– Export: high-organic or debris-laden spoil that cannot meet structural needs.

Final grading brings the picture into focus. Drainage planes are carved so water leaves structures, not toward them. Pads are trimmed within tight tolerances to support foundations and pavements. Proof-rolling verifies bearing; soft spots are excavated and replaced before they become future warranty calls. When excavation finishes with a sound subgrade and a manageable stockpile plan, subsequent trades can move in with confidence that the ground will behave as intended.

Demolition: Taking Structures Down Safely and Responsibly

Demolition is more than brute force. It’s an orderly reduction of a structure to components that can be sorted, reused, or recycled, while controlling dust, noise, and vibrations. The approach depends on building size, materials, and proximity to neighbors. Mechanical methods use attachments to break, shear, and crush. Selective demolition, sometimes called deconstruction, removes valuable elements first—metal, fixtures, hardwoods—before the shell is processed. Full structural takedown follows a planned sequence so loads transfer predictably and debris falls within controlled zones.

Preparation sets the safety baseline. Utilities must be verified shut and capped. Hazardous materials surveys identify items that require specialized abatement, such as certain insulation types, lead-coated surfaces, or refrigerants. Once cleared, crews establish exclusion zones with signage and spotters. Water mist is often used to suppress dust at the source, especially during concrete and masonry processing. Noise is managed by working hours, equipment selection, and distance; shielding may be added near sensitive borders.

Material diversion is both environmental stewardship and cost management. Separating metals, clean concrete, and dimensional lumber from mixed debris can significantly reduce landfill tonnage. Many projects see substantial diversion rates when a sorting plan is integrated early and space is provided for roll-off containers or stockpiles. Concrete may be crushed for base course, reinforcing steel recycled, and clean wood redirected to reuse streams. These choices reduce tipping fees and the number of truck trips, which matters in congested areas.

Method selection weighs speed, control, and salvage:

– Mechanical takedown: straightforward and relatively quick; high control, moderate salvage.

– Selective deconstruction: slower; maximizes salvage value and reduces mixed waste.

– Specialized techniques: reserved for unique structures; require advanced planning and broader safety perimeters.

Good documentation closes the loop. Waste tickets track volumes and destinations. Daily logs record progress, inspections, and any unexpected discoveries such as hidden voids or undocumented utilities. By treating demolition as a precise operation—rather than a noisy afterthought—contractors protect adjacent properties, recover value from materials, and deliver a clean slate for the work to come.

Permits, Environmental Stewardship, and Choosing the Right Contractor

Permitting brings accountability and clarity to land clearing. Authorities commonly require site plans that show erosion controls, access points, and stockpile locations. For larger sites, a stormwater plan outlines how sediment will be contained during rain events—think silt barriers, stabilized entrances, and inlet protection. Where sensitive habitats or waterways are near, additional measures and buffers may be mandated. Inspections confirm that controls are in place and functioning as conditions change.

Environmental stewardship is practical risk management. Protecting topsoil stockpiles with cover reduces wind-blown fines and preserves moisture for later reuse. Tree protection zones prevent root damage to specimens slated for retention. Fueling and maintenance areas are set on stable ground with spill kits at the ready, and designated washout areas keep concrete and slurry waste from entering drains. Wildlife timing windows may affect clearing schedules in some regions; aligning activities with these windows prevents costly stoppages and fines.

Budgeting and scheduling benefit from transparency. Clearing may be priced by acre or by task, while excavation tends to be driven by quantities and haul distances. Demolition costs hinge on structure size, material types, and diversion goals. A sensible plan includes a contingency to absorb surprises—unsuitable soils, buried debris, or undocumented utilities. Line items help compare proposals clearly, for example:

– Clearing and grubbing: area, expected vegetation density, disposal plan.

– Earthwork: cut/fill volumes, import/export assumptions, compaction criteria.

– Demolition: structure description, abatement allowances, recycling targets.

– Controls: erosion measures, temporary access, monitoring and testing.

Selecting a contractor is about fit and foresight, not just price. Ask for project histories that resemble yours—similar soils, site sizes, and urban or rural contexts. Review safety performance, training programs, and near-miss reporting habits. Inspect equipment condition on a job visit; well-maintained machines reduce downtime. Talk through sequencing: how access will be built, where material will be staged, and how weather risk will be managed. Clarify responsibilities for testing, surveys, and permits to avoid gaps.

A strong partnership is built on communication. Regular check-ins keep scope aligned and reveal small issues before they become schedule threats. Clear change procedures mean unexpected conditions can be addressed swiftly and fairly. When contractor and client share a realistic plan, track progress with measurable checkpoints, and stay responsive to conditions on the ground, land clearing evolves from a potential bottleneck into a reliable launchpad for the entire project.